System Introduction

S7-300 PLC programmable controller is a modular system, it with convenient and economy to meet the requirements of medium performance control. We used in grinding calcium carbonate production line of adopted SIMATIC S7-300 and industrial control computer automatic control system, with advanced Siemens WINCC PC monitoring software, monitoring the full function of control system to fully meet the requirements of the automatic control system.

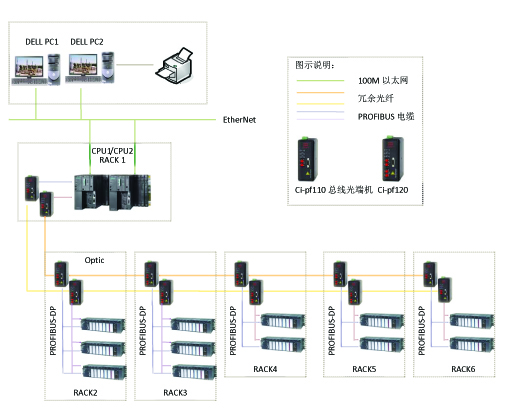

The system USES Siemens CPU - 315, through the CPU integration of PROFIBUS DP communication interface connect to Ci-PF110 Fiber optic repeater, and through the optical fiber interface link to Ci-PF120, then connect to other distributed I/O substation step by step to built a data communication (see below), through PROFIBUS communication protocol to control two large capacity danfoss frequency converters and respectively get the data collection from the CPU, when one of the industrial control system failure, another industrial PC will not be affected, which ensures system continues to run normally.

Networking Structure

Functional Introduction:

Support the profibus-dp industrial control field bus protocol, the communication rate of 0 ~ 12 m adaptive.

The electrical interface with the 1500 v voltage isolation and 600 w surge protection function.

The single fiber port/dual chain network support.

The DC9-30 v wide power input, dual power supply redundancy, DC1000V power isolation, reverse connection protection.

Provide fiber optic link and power failure alarm relay output.

IP30 protection grade, wavy lines aluminum strengthen casing, with a standard 35 mm guide installation industry.

Conclusion:

The system adopts the Ci-PF110 and Ci-PF120 bus data optical transceiver PROFIBUS bus optical fiber transmission solves the electromagnetic interference, ground loop interference and lightning damage problem, improves the control signal reliability, security and confidentiality, also solved the problem of the short transmission distance. Greatly reduces the optical fiber communication hardware cost. For the user, It can solve the traditional scheme import product price high, long period of delivery and a series of new problems, independent research and development of Shenzhen Comark Technology Co., Ltd Ci-PF series bus data optical transceiver with the advantages of stable performance, convenient and easy to use, is worthy of popularization and application in the field of automation control system for optical fiber communication.